test cans

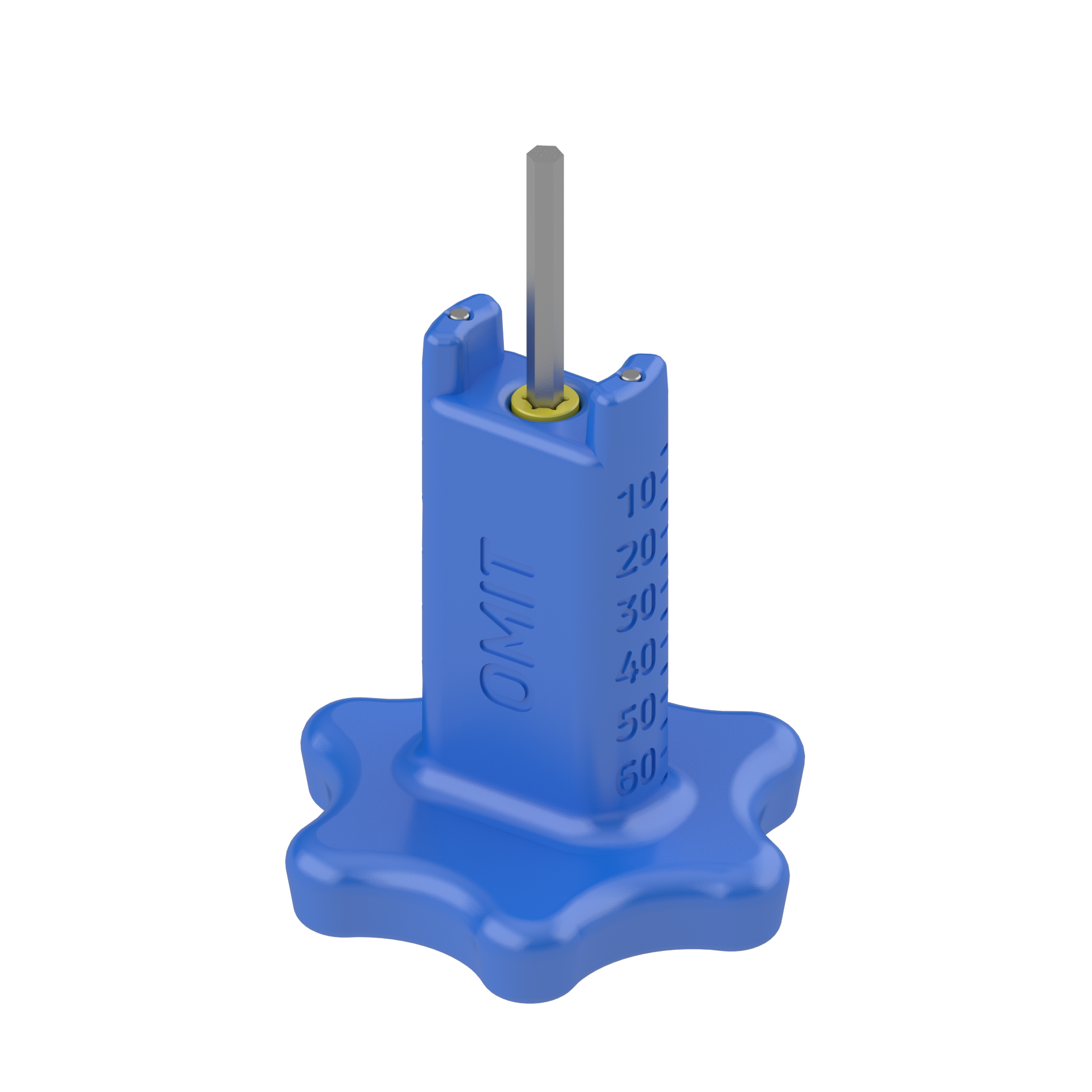

NOMITECH Inc. is pleased to present their line of OMIT adjustable Test Cans. These robust plastic cans are designed to mimic the fill level inside a can to verify the correct height settings of gamma / X-Ray based fill level inspection equipment. After many frustrating experiences with test cans from other manufacturers, we believe this to be the best design on the market.

We currently manufacture these test cans in all standard sizes for the North American and European markets. We can also produce custom sizes. Please contact us to order a product suitable for your application.

Our GO (Green) and NO GO (Red) fill level test cans, with an easily adjustable fill slug height. These serve to ensure that fill level systems are accurate and are tuned to the correct height.

All of our adjustable height test cans may easily have their fill height set with our universal adjustment tool. They are then securely locked to prevent changes. Our newest design incorporates an internal 3 point cam locking system to prevent damage from excessive force.

Our adjustable fill slug cans with the optional Good Lid metal insert, along with the Missing Lid Challenge can. These are designed to ensure proper functioning and height settings of equipment checking for fill level and can lid presence.

Our weighted Reject Challenge can is designed to test the capabilities of and ensure proper rejection of failed product from the line.

Finally, our Good DUD (with Adjustable Fill Level - Red and Green) and Adjustable Dud cans. These are designed to work with equipment that checks for proper product pressurization by comparing the height of the center of the lid with respect to the outer chines. When incorporated with a fill level system, the Yellow Adjustable DUD will be detected as a “Good Fill” while challenging the pressure detection system.

General Features:

Water and oil resistant double wall design

Resilient, impact resistant plastic for long term, repeated testing

Gamma / XRay readings closely match normal liquid readings

Verifies fill height setting and gamma thresholds better than competing devices

Fill Level height readily visible for confirmation on standard cans

Easily slips on conveyor to allow for rapid insertion in to production line

Stainless heel to reinforce bottom and minimize wear / height change on most styles

Cans designed to mimic production cans for optimal triggering / rejection

Special tool to allow for fill height changes only by approved personnel - with lock

Standard North American and European sizes

Custom sizes available by request

OPTIONS:

Stainless Weighting on Reject Challenge can to test rejector more effectively